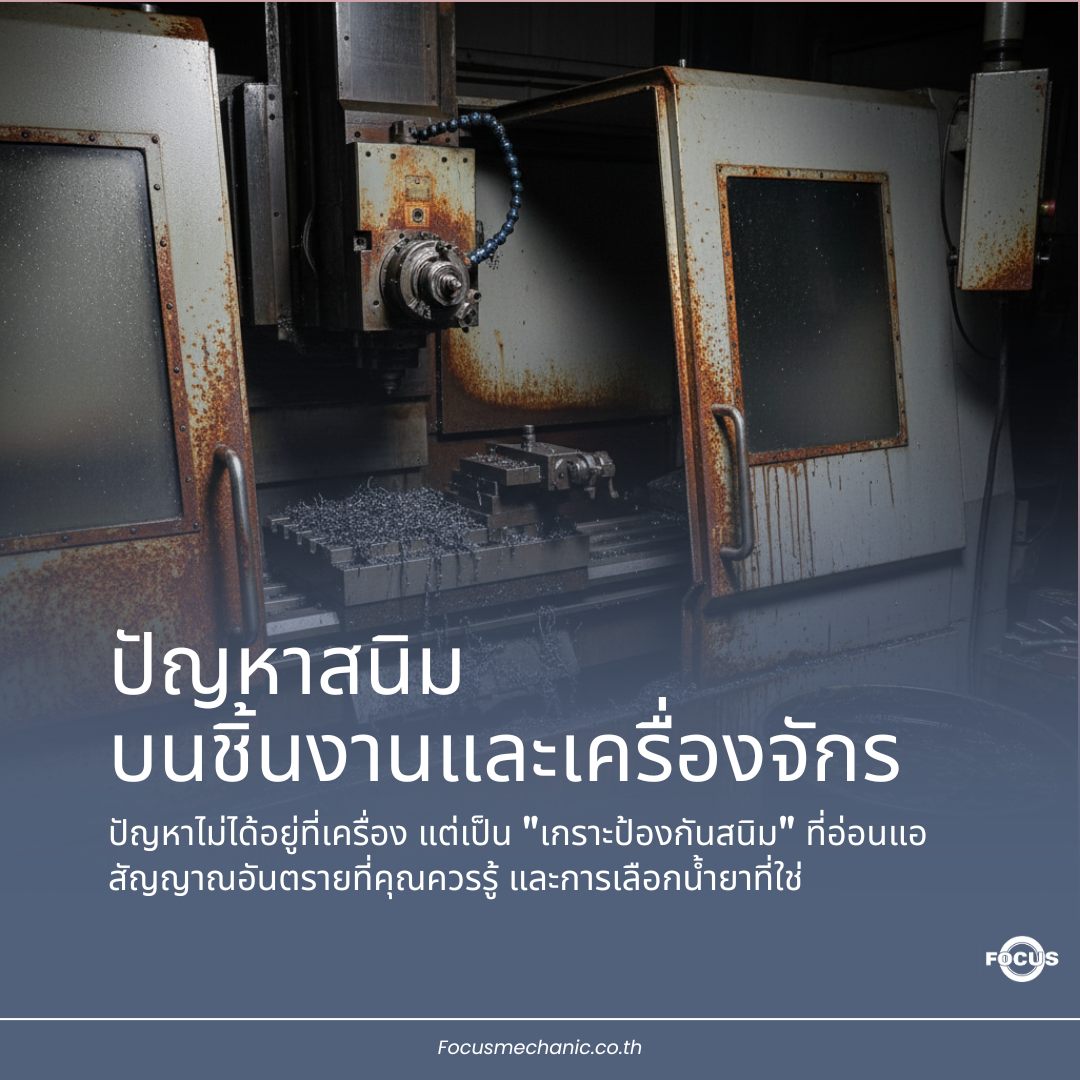

Stop Rust! 3 Reasons Your Coolant Fails & Machine Rust Solutions

31 Oct 2025

Getting rust on your parts and machines, even though you're using coolant? That's a sign that your "anti-rust shield" is failing!

Here are the 3 main reasons for premature rust and corrosion:

-

Concentration is too low: When the fluid is diluted, the Rust Inhibitor weakens and can no longer form a protective film on the metal surface.

-

pH level drop: A pH value below 9.0 indicates slight acidity, which greatly accelerates the oxidation reaction that causes rust.

-

Poor water quality: The water used for mixing has high contamination of chlorides or sulfates. These substances directly attack the metal surface.

How to Prevent It

-

Choose a High-Performance Fluid: Select a coolant with a high-quality, durable Rust Inhibitor suitable for the type of metal you are working with, ensuring a strong protective shield from the start.

-

Measure to be Sure: Regularly check the concentration with a Refractometer and check the pH value of the fluid, at least once a week.

-

Use High-Quality Water: Use purified water (e.g., RO or DI water) for mixing and topping up the fluid to avoid the accumulation of harmful minerals.

At Focus Mechanic, we offer coolants that provide excellent rust protection, and we also provide lab services to check the quality of your fluid so you can be completely worry-free about any problems that may arise with your coolant.